Key Specifications/ Special Features:

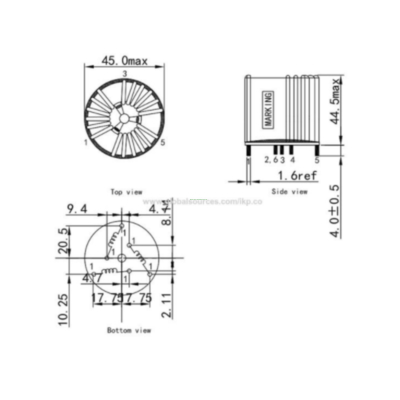

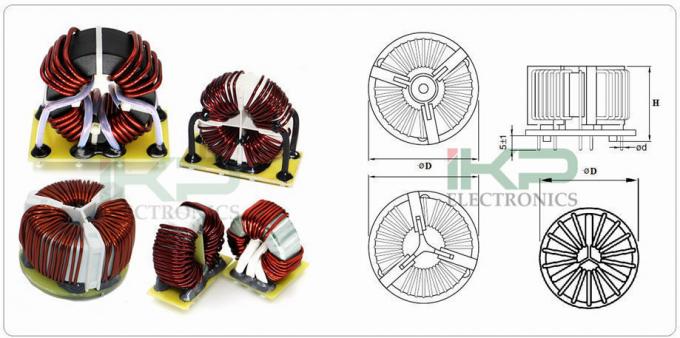

A large range of toroidal common mode chokes is available, all type of material are used and especially nanocrystalline material which allow a standard range from 0.3 A up to 50 A and far more on custom designed products. All mountings are available, vertical, horizontal, bare coil, and a new range of SMD power chokes.

Characteristics:

Application up to 760 VAC

High permeability MnZn Ferrite or nanocrystalline core material

Improved insulation through plastic case and winding spacer

Patented design

Specification according to EN 60938-2

Air and creepage distances ≥ 7 mm

Rated current up to 46 A

Attenuation up to 60 dB

Suppression frequency range: 1 kHz to 20 MHz depending from used core material

Operating temperature: -40 °C to +125 °C

Flammability corresponding to UL 94 V-0

Applications:

Power electronics

Power line input filter

Radio interference suppression in motors

Suppression for common mode noise

Frequency converter

Power supplies

Charging stations

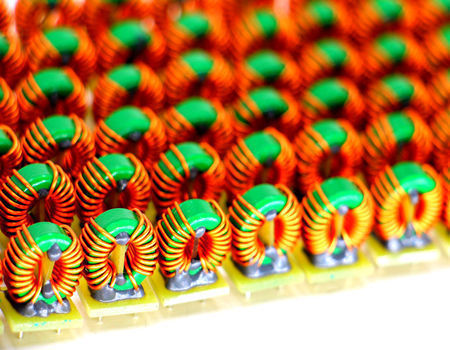

IKP relies on 20 years of manufacturing experience, targeting photovoltaic solar energy, new energy, 5G, IOT, EV and other fields, optimized and improved traditional common mode inductors, and obtained a number of high-quality products with independent property rights. IKP cooperates with the Institute of Magnetic Materials every year to develop a batch of magnetic cores with new formulations to meet the product requirements of special customers. More and more high-end customers choose and trust us, which greatly enhances our confidence.

IKP inspects every product in strict accordance with ISO standards to ensure the excellent quality of the products. We use raw materials from well-known brands at home and abroad, and can provide SGS reports for all raw materials. Each batch of products can be traced back to specific quality information. Because of this, IKP has a good reputation and brand effect in the world.

IKP continues to transform and upgrade production equipment, with higher and higher automation levels and better and better product consistency. The number and quality of skilled workers ensure the rapid mass production of IKP. Today, our three production bases can produce 1KK inductors per day. The personalized packaging allows the product to be perfectly presented in front of customers.